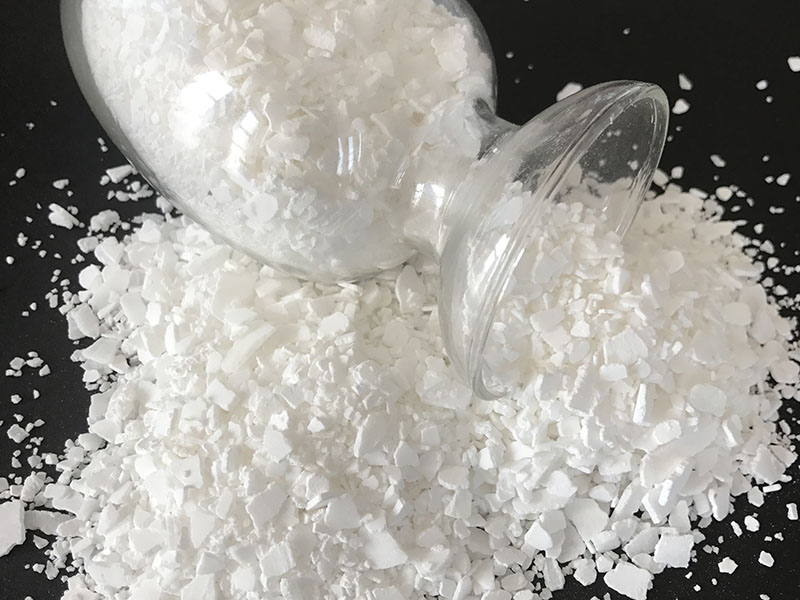

Calcium Chloride for Oil & Gas Drilling

Calcium Chloride is used in establishing and maintaining oil and gas wells. It helps well fluids gain needed consistency, increases density and stabilizes shale formations. As a completion fluid it seals well casings and displaces drilling mud. In short, Calcium Chloride is used in several applications for new or existing wells to improve efficiency and production. Calcium Chloride Prills are used in gas and oil drilling. It helps keep gases from forming and helps sludge from getting out of hand.

Drilling Muds:

Calcium Chloride is used in drilling mud to cool and lubricate the bit and to remove cuttings from the hole. Calcium Chloride helps add density to the mud to overcome formation pressures and keep oil, gas, and water in place. Calcium Chloride inhibits clay and shale hydration, adds needed weight to overcome formation pressure, aids in carrying cuttings to the surface, and is easily diluted from more concentrated solution.

Completion Fluids:

Calcium Chloride is used as a completion fluid just before the producing formation is reached to flush the hole clean of solids so the casing can be cemented into place. As a clear, solids free brine, Calcium Chloride is ideal as a completion fluid with a density range of 10 to 12 pounds per gallon.

Concrete Accelerator:

As a pipe that runs from the reservoir to the surface, the casing is usually cemented into place to ensure a pressure tight connection to the oil and gas reservoir. The concrete also prevents caving, confines production to the well bore, and provides a way to control well pressure. Calcium Chloride dramatically cuts set time for the concrete and can be used down-hole to several thousand feet.

Packer Fluid:

Once the casing is cemented into place, a smaller diameter pipe, the tubing, is inserted into the casing. Tubing makes the flow of oil or gas more efficient and can be replaced if plugs develop or it is damaged. Tubing is used with a packer fluid that keeps the well fluids away from the casing to minimize corrosion. The tubing packer combination reduces well pressure on the casing and reduces the chance that a casing leak could become a blowout. Calcium Chloride is used in packing the annular space between the tubing and the casing. It helps maintain pressure levels because it has sufficient density to offset the pressure on the casing.

Workover Fluid:

Calcium Chloride is used as a workover fluid, flushing wells free of solids before they are repaired or before reworking a well that has been idle for some time.

Onshore and offshore oil and gas producers rely heavily on custom-formulated clear brine fluids containing calcium chloride for all types of drilling and completion applications. These fluids are used in oilfield completion and workover operations to reduce water activity and create osmotic forces to prevent absorption of water by shales. The divalent calcium ion inhibits clay swelling, dispersion and migration. Water containing high concentrations of calcium chloride can be used as a kill fluid in production wells, especially those containing heavy concentrations of carbon dioxide.

Packaging:

25kg plastic woven bag

500kg plastic woven bag

1000kg plastic woven bag

1250 public plastic woven bag

50lb PE bag or paper-plastic composite bag

80lb PE bag or paper-plastic composite bag

Special customised packaging: e.g. cardboard drums